SUMMER 2016

Commercial Construction

SE Portland

In deep Southeast Portland, Fairlane coffee shop was part of a new construction project during the spring and summer of two-thousand sixteen. I signed on to design and build the interior elements just after the sheetrock was hung, back when it wasn’t much more than an empty concrete box. It was fun to work with the founder to develop ideas of how the space should flow, sketch out various floorplans, and decide which materials would work best.

While the plumbing permits were being finalized I prepped as much of the cabinet frames, tabletops, and bars as I could in my backyard shop. Once development services signed off on final utilities, I trucked everything over.

We decided on concrete countertops, so sturdy frames of half-inch, by one and one half-inch, steel served as a base, which I could anchor into the four-foot stemwall. I poured the countertops inverted on the floor using simple two-by-four forms on four-by-eight sheets of eighth inch black plastic. If I remember correctly the mix was Portland cement, one-seventy grit sand, and a few bags of one-inch fiberglass fibers, no gravel. I used the same mix for the backsplashes, which I was able to pour just a half-inch thick with all that fiberglass binding.

Slabs poured and starting to set

Slabs in place with holes drilled for utilities

Welding the anchor points for the Menu / Cabinet

Steel frames for the kitchen corner

Salt and vinegar rust patina etching into the kitchen island

Welding the base for the communal table

The glulam for the corner bar getting a pass on the four-foot wide belt sander

One of the Four-tops coming together back at the shop

After a few days, once the mix had completely set, it was satisfying to crack off the forms, flip the fresh slabs over, and lift them into place. I set them with Lexel, which is a crazy co-polymer rubber that won’t let go, but takes weeks to fully cure. In the meantime, I filled any little pockets with a slurry and burnished the surfaces. I finished all the countertops by building up a bunch of coats of Cheng’s Concrete Sealer, where you increase the amount of acrylic with every pass until you hit one-hundred percent, and then two more passes. Concrete is like a sponge that wants to absorb acrylic until it hits a critical mass.

The ten-foot long communal table serves as the centerpiece of the shop. I used a salvaged glulam beam and ripped it down to one and a half-inch thick on a Lucas Mill and then surfaced it with the giant belt sander seen on the edge of my crazy workshop in a photo up above.

The base is welded from fourteen-gauge steel, which I put a patina on with salt and vinegar, a week or so out in the weather to rust over, and then an oil finish. The bottom section has a magnetic panel that can be removed to access concrete anchors, which hold it in place.

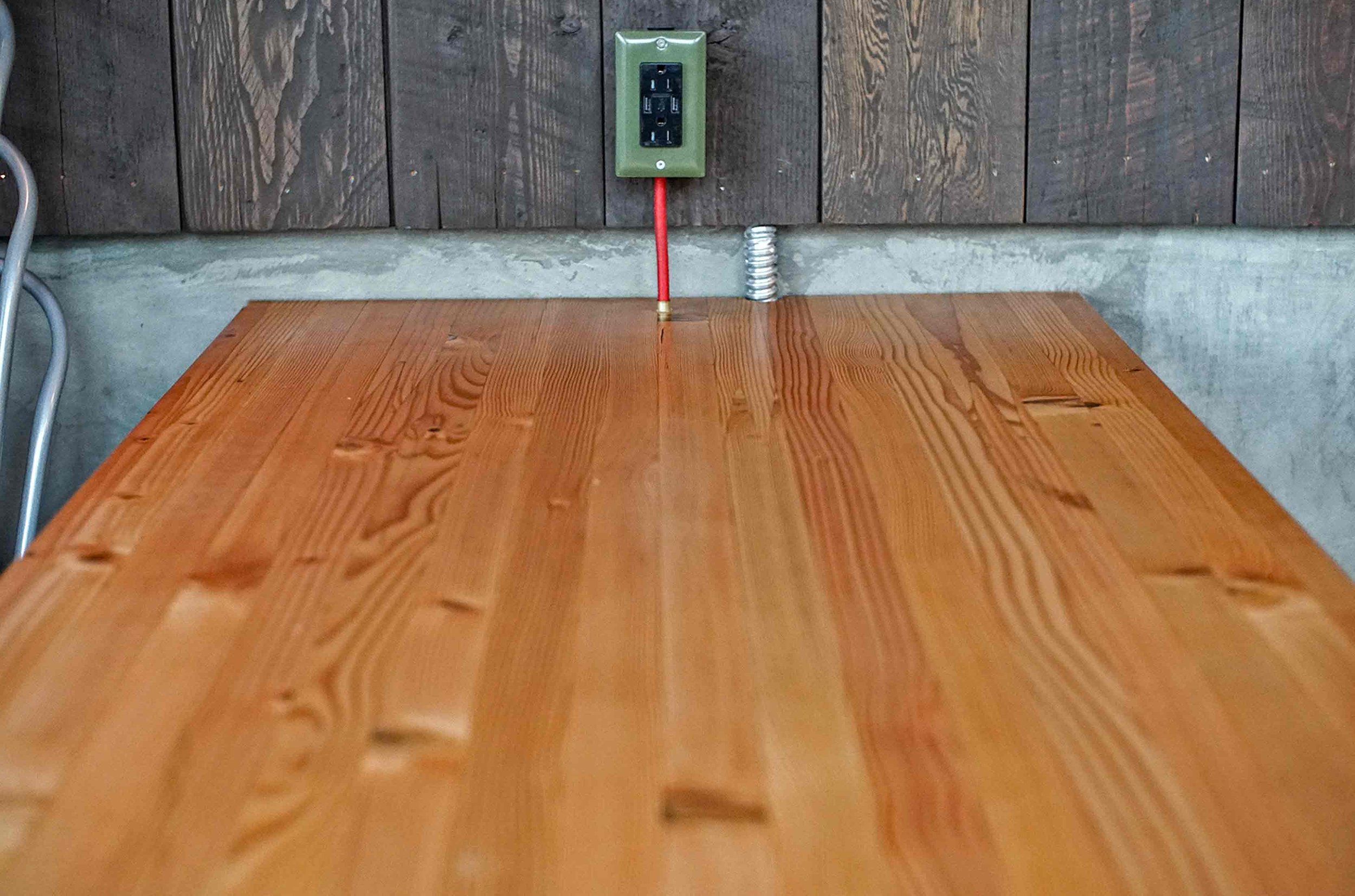

I utilized the same rustic-patina process on all of the cabinet faces, the service island, the overhead menu board, and any brackets for tables, and the corner bar. As the kitchen started to take shape we moved into covering the walls with reclaimed barn wood with a dark Kona stain. For the power outlets I drilled a line through each glulam tabletop for a clean access point with USB options.

Kitchen corner taking shape

The finished patina on the lower cabinets

Simple angle iron handles on 1/8" steel doors with soft-close magnets

Lower angle on the communal table

The corner bar looking out on Milwaukie Ave

The three four-tops designed for easy mopping

The finished kitchen corner

A detail on the mini-bar with steel brackets and concrete anchors

Power ports above and through the tables

Hydration station

The corner sink all plumbed up

Quality control picking their seats/noses

The finished kitchen area

While we still lived in Portland I would always try and meet with construction clients at Fairlane. The shop really helped me cross the bridge from my own personal residential projects into commercial endeavors, which factor in public interaction. I still love to stop by the shop when I’m in the neighborhood, but these days that’s fairly few, and far between.